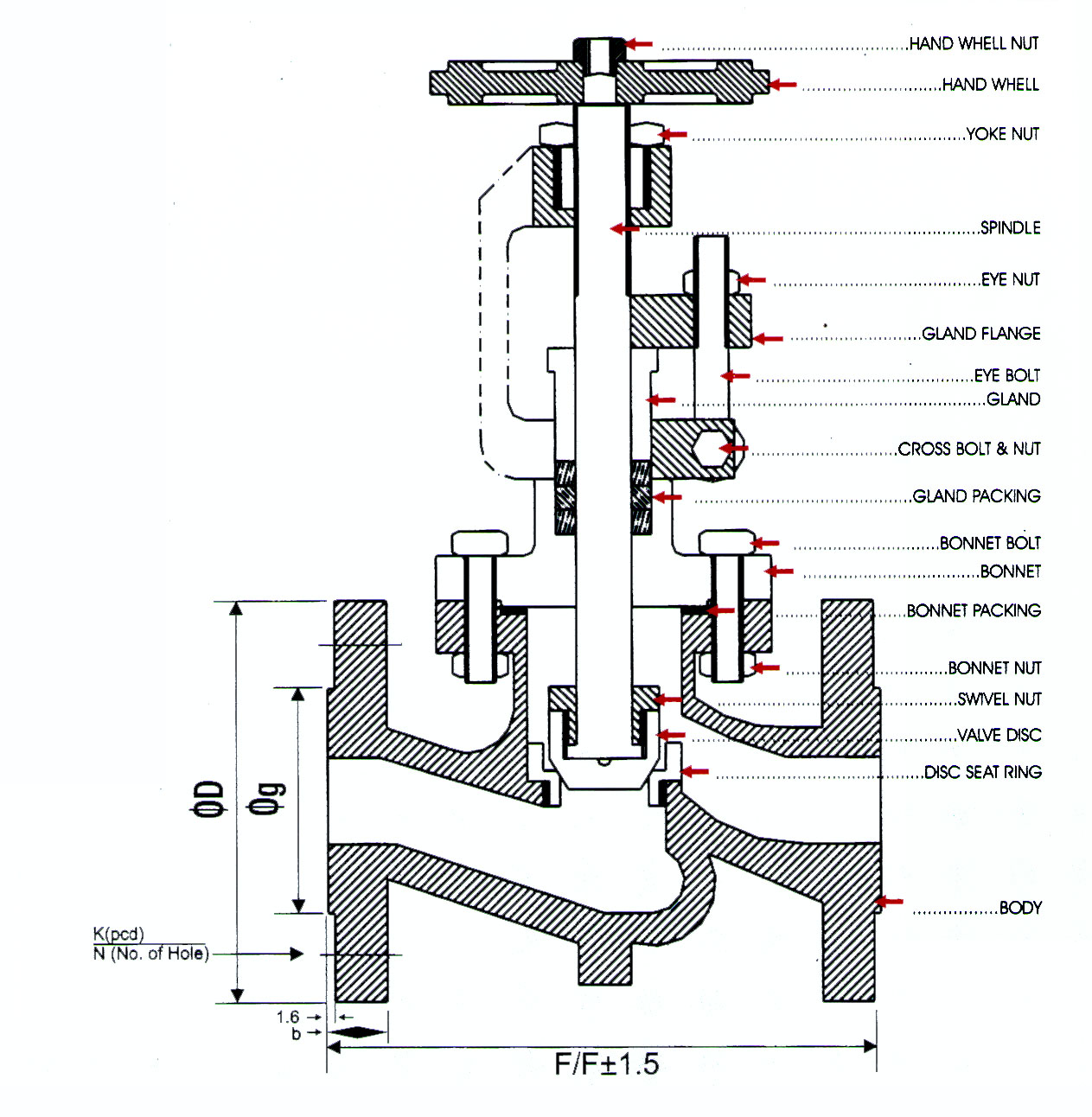

Product Overview

DIN STD. ND-40 :

We manufacture all types of Globe Valves under our brand VIPUL. They are available in On-Off Disc, Control Disc and Parabolic Disc types. 'VIPUL' Globe Valves are manufactured in almost all material like C.I, SG IRON, WCB, LCB, WC-1, WC-6, WC-9, CF-8, CF-8M, CF-3, CF-3M, CN-7M, HV-9, CD4-Cu., Hastelloy etc. Product range commences from 06 NB through 400 NB in size and BS/ANSI 150# through 2500# and PN-10 through PN-250 in pressure rating. STELLITE trim are provided for all Valves of 600# and higher ratings as a manufacturing standard of 'VIPUL' Valves and in lower rating on special requirement.

Vipul Cast carbon Steel Globe Valve is most suitable for high temperature and high pressure applications for a wide range of fluids Vipul Valve is provided with one Graphite ring to restrict gland leakage,supported with numerous Graphited Spiral wound gasket packing, specially for high temperature application.

| GLOBE VALVE | |

|---|---|

| ( DIN STD - ND - 40 TYPE ) | |

| MANUFACTURING STANDARD | DIN 3230 |

| TESTING STANDARD | DIN 3230 |

| FACE TO FACE AS PER | DIN 3202 |

| MOC | ASTM A 216 GR. WCB [ Cast carbon steel ] |

| Working Parts | |

| Disc Seat Ring | AISI 410 Hardened & Lapped |

| Valve Disc | AISI 410 Hardened & Lapped |

| Swivel Nut [Valve Disc Lock Nut] |

AISI 410 |

| Spindal | AISI 410 Hardened & Lapped |

| Packing | |

| Bonnet Packing | Graphited Spiral wound & Gasket |

| Gland Packing | Graphite Ring |

| Working Pressure & Temperature | TESTED AT |

| TESTED PRESSURE AT | TEMPERATURE | ||

|---|---|---|---|

| HYDROSTATIC | |||

| BODY | SEAT & BACK SEAT |

||

| 60 KG/cM² | 40 KG/cM² | 900 °C | |